HRC provides agile 360° engineering and material testing solutions to develop lightweight, durable, cost-efficient components within short timeframes, optimizing clients' products and competitiveness.

Design Feasibility

-

Understand Requirements

-

Market Study

-

Material Definition & Process Recommendation

-

Engineering Feasibility

Analysis -

Concept Development & Structural Design

-

Cost Estimation

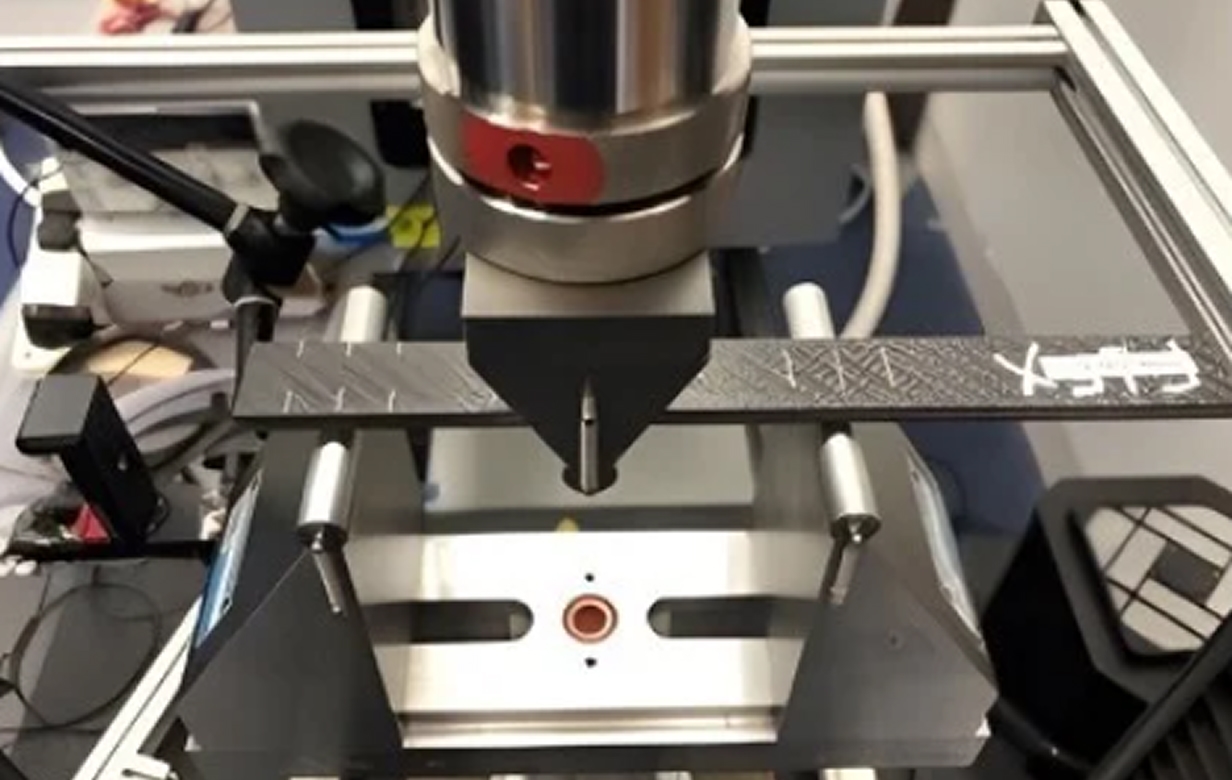

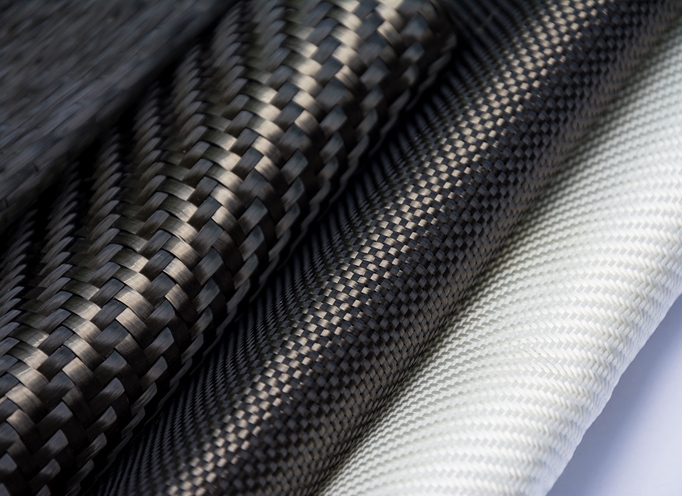

Material Screening & Testing

HRC conducts a wide range of physical tests to capture essential structural parameters, allowing us to rank materials based on predefined criteria. Through in-house testing, material behavior can be quickly adjusted and optimized for specific applications. Our testing capabilities cover fiber composites, metals, adhesives, and core materials. To support accurate predictive modeling, we provide validated material cards for industry-standard simulation tools, including Abaqus, LS-DYNA, and Radioss.

Accurate analysis predictions are reliant on precise material properties.

Tension

Compression

Shear

Impact

Flexural

Fatigue

Environmental Testing

Structural & Failure analysis

Adhesive and joint characterization

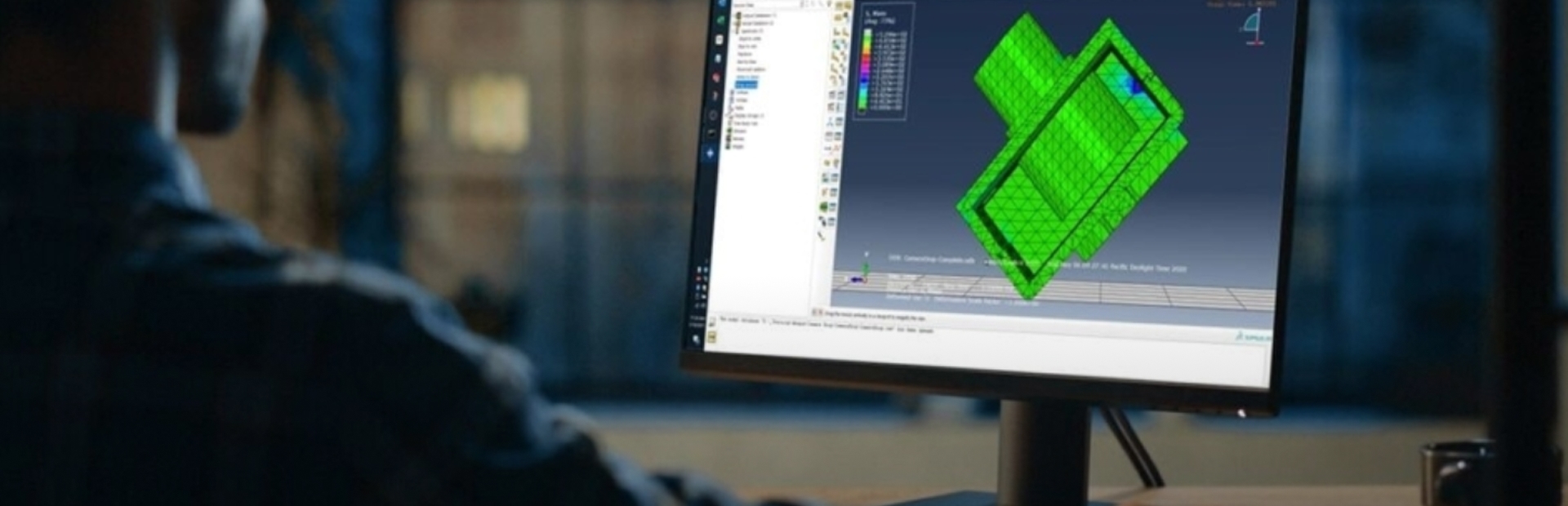

Predictive Analysis & Simulation

HRC leverages predictive analysis, including Finite Element Analysis (FEA), to validate and optimize product performance across metals, composites, and hybrid structures. By replicating real-world conditions virtually, we reduce development time, minimize physical iterations, and ensure each design meets both functional and manufacturing requirements.

-

CRASH SIMULATIONS

Dynamic Explicit Analysis for High-Speed Crash Events

Energy Absorption & Composites Crush

Crashworthiness Evaluation

Structural Integrity

-

STIFFNESS & STRENGTH

Static/quasi-static simulations for structural integrity and load capacity

Implicit Analysis

-

FATIGUE & DURABILITY

Fatigue life & durability under cyclic loads

Life Prediction & Damage Evaluation

Analyze failure modes

-

NVH ANALYSIS

PSD Random vibration analysis

Frequency response analysis

Transient response analysis

Modal analysis

Design for Manufacturing

-

Planning

Consult with manufacturing experts on your design. Lowering manufacturing costs is never easier than at the design stage.

-

Material selection

Selecting the best materials for your product, balancing performance, cost, and manufacturability.

-

Processes

ldentify the manufacture process and technologies to minimize costs and time-to-market.

-

Homologation

We guide you through certification and homologation processes, ensuring your product complies with all necessary industry regulations and standards.