At the HRC Automotive mass production center, we work closely with OEMs worldwide to develop innovative and complex projects, ranging from interior and exterior panels to structural components and monocoques, driving advancements in the automotive industry.

-

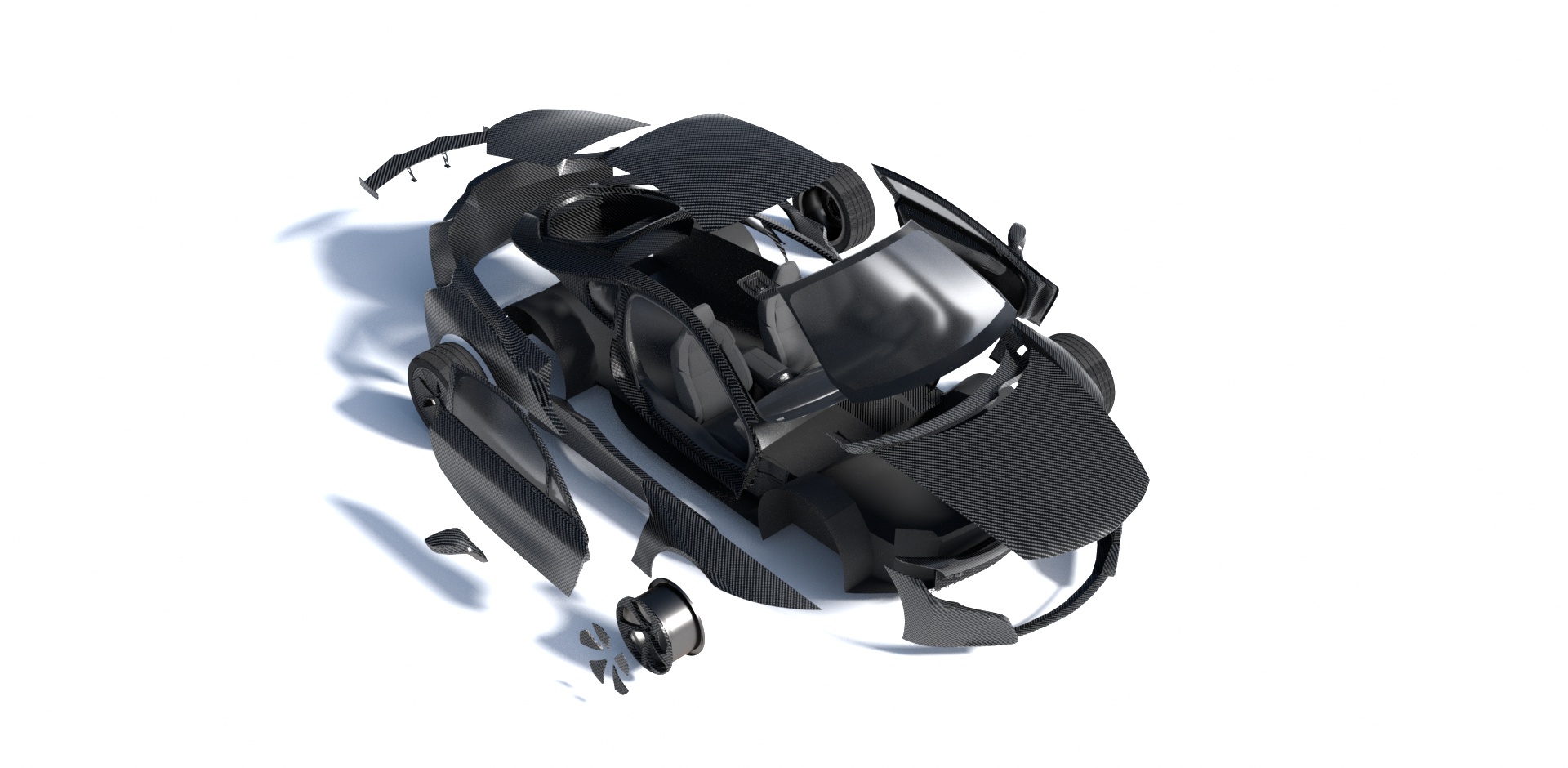

External view

-

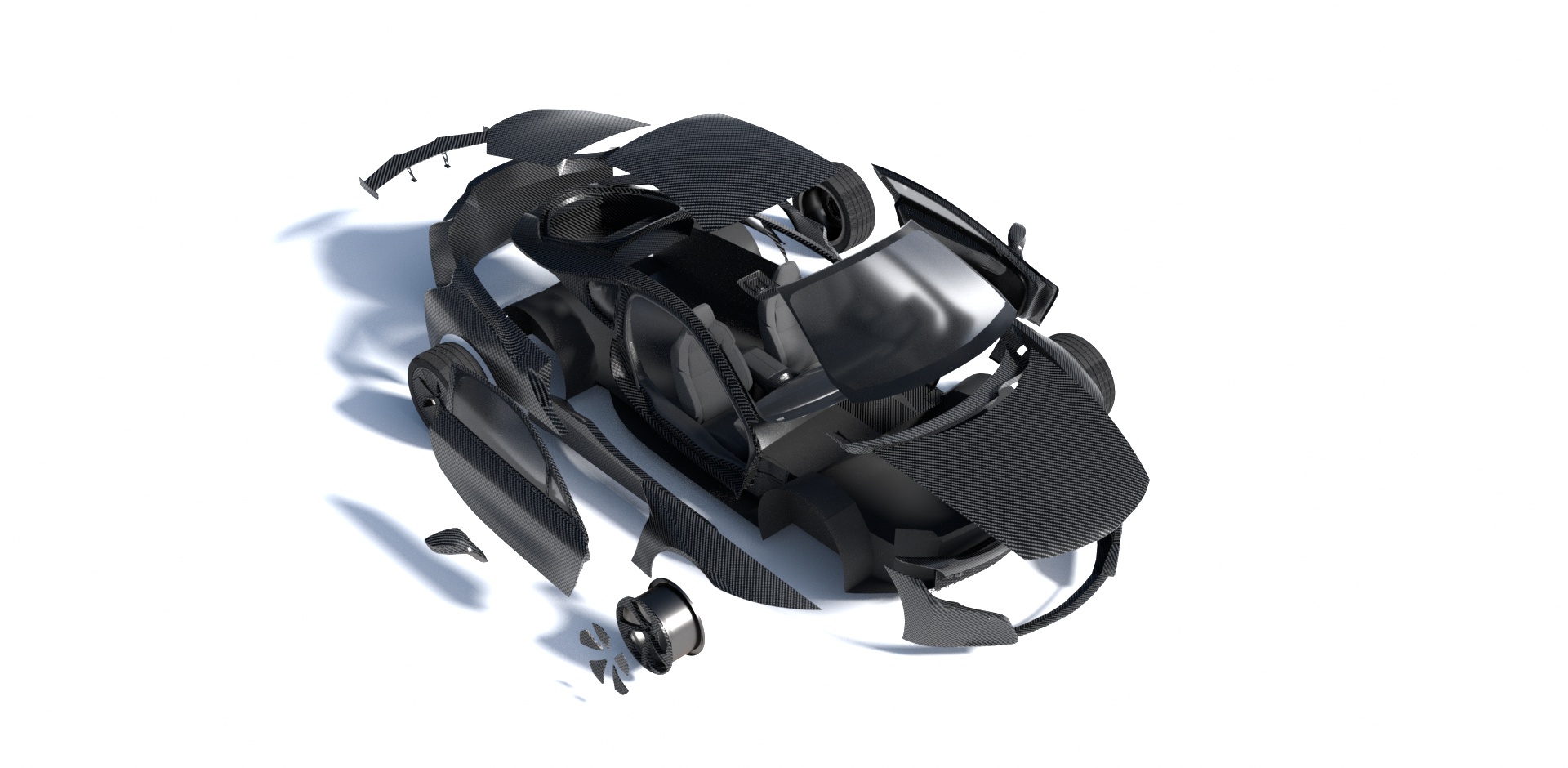

Internal view

-

-

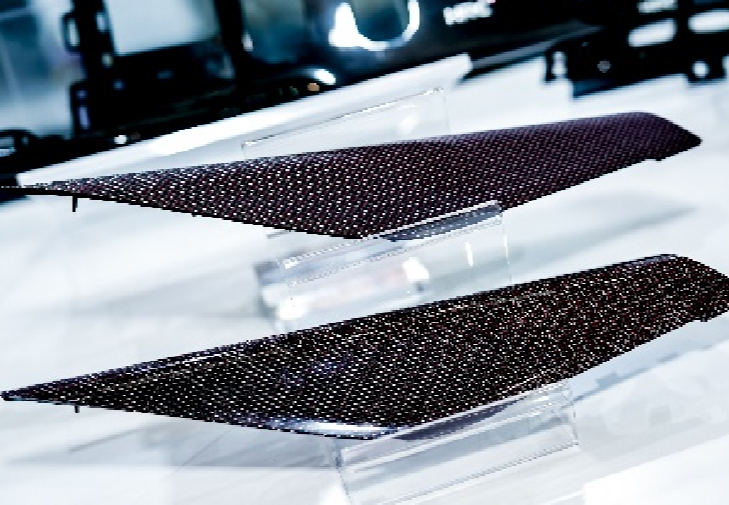

Rearview mirror

-

Door

-

Wheel insert

-

Wheel

-

Fender

-

Front bumper trim panel

-

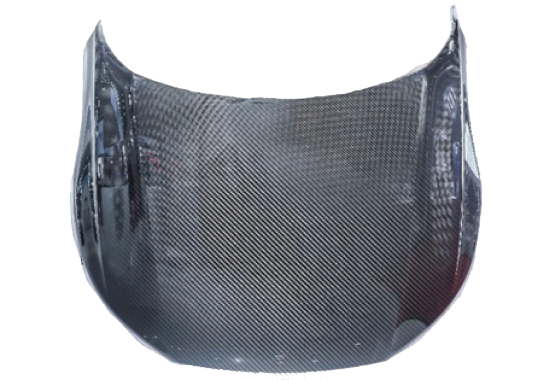

Hood

-

Roof

-

Monocoque

-

Body side panel

-

Rear bumper lower trim panel

-

Rear door

-

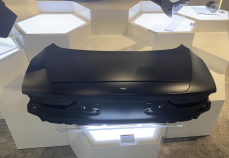

Spoiler

-

-

-

Switch panel

-

Trim assy-steering wheel

-

Interior trim

-

Reading lamp panel

-

Seat switch panel

-

Seat trim panel

-

Center console finisher panel

-

Reinforcement rear floor panel

-

Seat back cover

-