HRC develops and refines innovative composite solutions that drive the advancement of renewable energy technologies. Through ongoing research and product evolution, we contribute to enhancing the efficiency and sustainability of clean energy systems.

Next-generation "plug and play" hydrogen storage system

Carbon fiber type IV hydrogen storage system

The system includes the On-Tank-Valve (OTV), Thermal Pressure Relief Device (TPRD), Tubing, Fitting and other necessary components.

-

Highlight

Hydrogen storage vessels adopts unique composite lay-up design and advanced winding process to achieve significant weight reduction.

-

Automotive battery box cover

Composite materials are becoming increasingly valued in the transport industry due to their very high weight-specific properties. In the context of electromobility, weight-specific battery capacity has an increasing importance as an evaluation criterion for BEV. To achieve high values of >180Wh/kg, innovative lightweight solutions of the entire battery system are necessary. One of them is locally reinforced Sheet Molding Compound (SMC) as a resource and cost-efficient process for the manufacturing of battery housings. The process combines the high mechanical performance of unidirectional carbon fiber (CF) prepreg material in areas where needed and the design freedom of SMC (CF or GF) as a compression molding material.

-

-

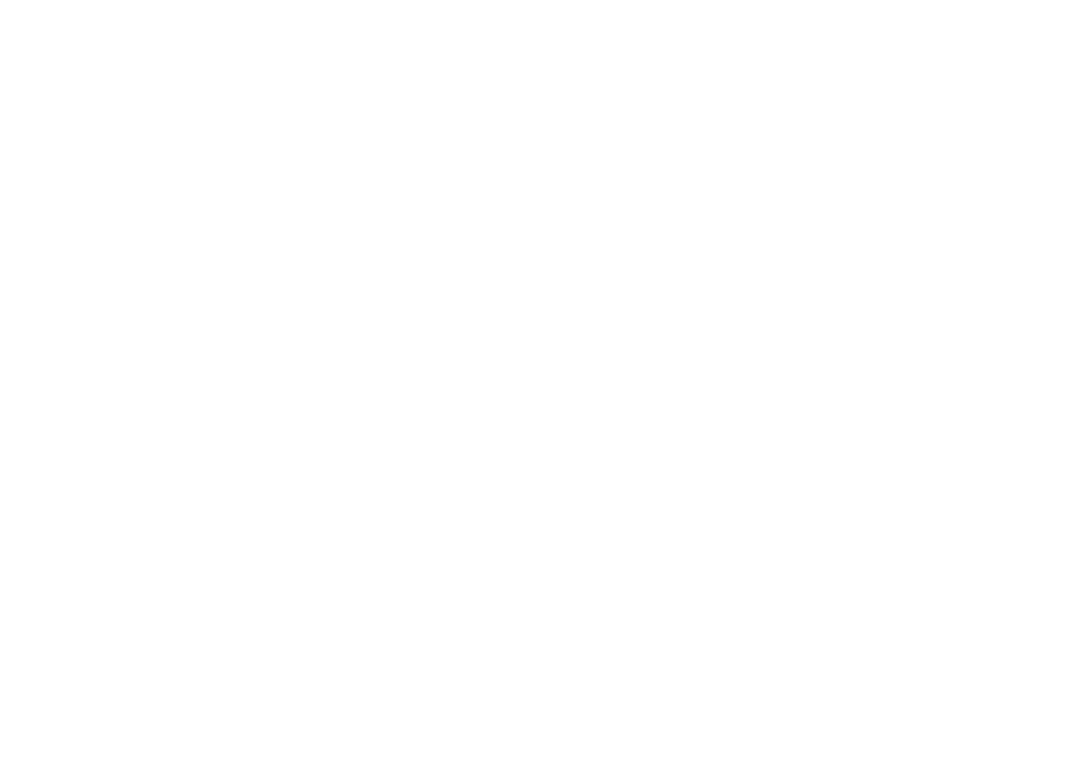

Cable core

Solid structure, with internal carbon fiber and external fiberglass (designable), maximum production speed of 65 cm/min (varying based on material system), and the maximum winding length on the spool is 5000 m.

-

-

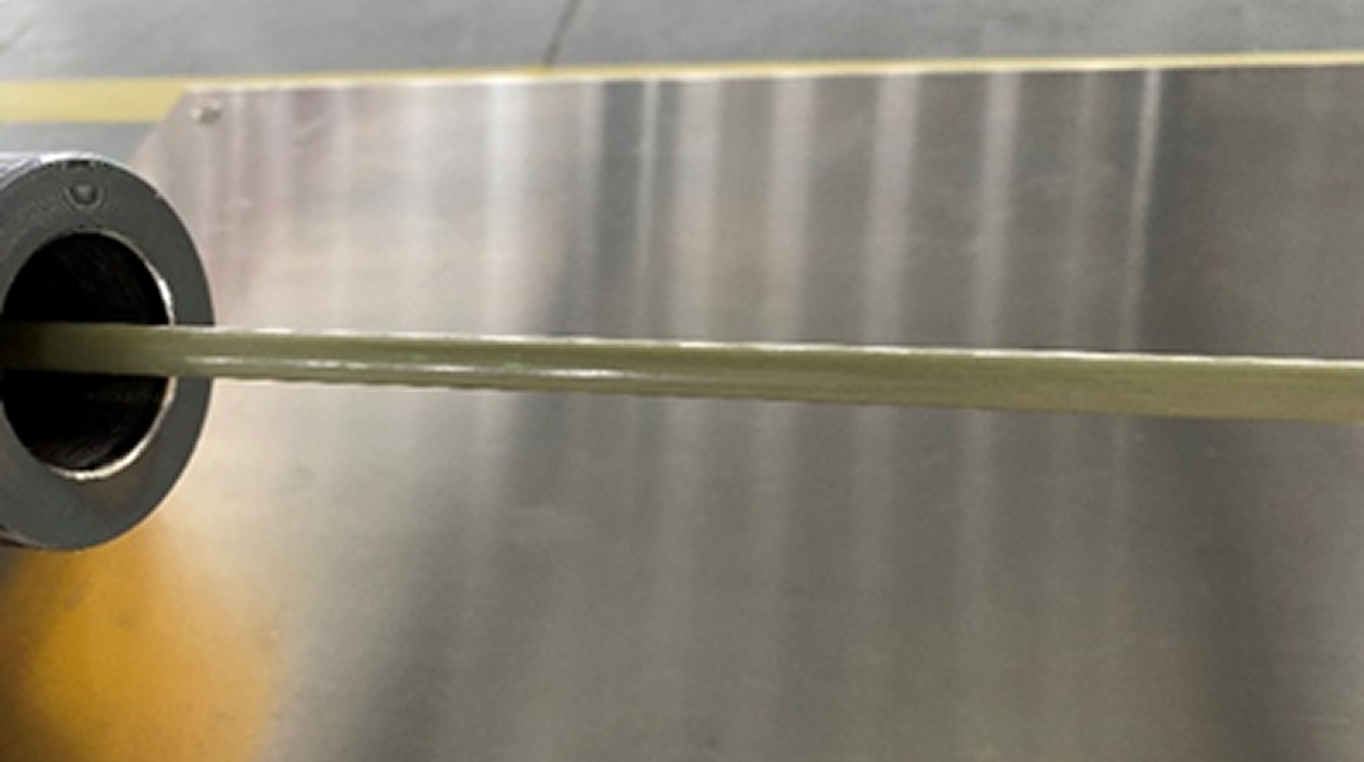

Beam plate

Structural beam for wind turbine blades, with the option to produce with or without mold release fabric on the surface, pure carbon fiber structure (designable), and the ability to combine with different matrices, such as epoxy, polyurethane, and thermoplastics, with a fiber volume content (FVC) of up to 60%.

-