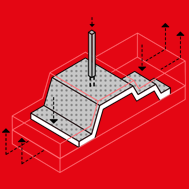

In HP-RTM (High-Pressure Resin Transfer Molding) process, the first step is building up a fiber preform. A very low-viscosity, reactive resin is injected into the cavity at high pressure ensuring that each individual fiber is wetted and that there are not any air voids

Mass production realized in short cycle time via automation

Superior component quality with highly reactive resin system

Cost reduction through optimized and continuous process

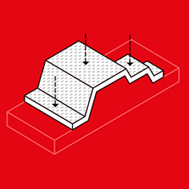

Unwind the fiber material and cut fiber blanks

Stack the blanks to create the correct layup

Preform to give the fibers their spatial orientation

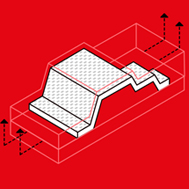

Transfer to HP-RTM tooling and apply vacuum

Inject resin, while maintaining vacuum and counterbalance the injection pressure by the clamping force of the press

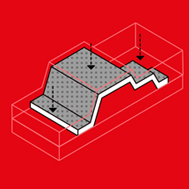

Cure the resin while maintaining pressure on the mold and demold the fully cured part

Multi Injection High-Pressure RTM process .

DISCOVER MOREAlternative mass production process to HP-RTM .

DISCOVER MORE